The manufacture of thin film coating is a growing industry worldwide and will continue to grow in the future. Vacuum film technology is roughly three decades old but the technology continues to be refined. More applications for the technology are being found every day.

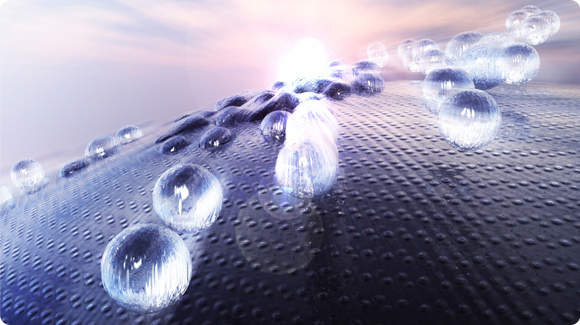

In Vacuum technology coatings, a strong vacuum chamber is created and the product to be coated is placed in the chamber. The coating material is then broken down to either a vapor or gas and deposited on the target product on a molecular level.

Depending on the coating substance, a number of techniques are used to break down the coating material, such as through lasers and electrical arching. Certain metals and other substances can be vaporized in this manner. The resulting vapor is deposited onto the targeted product. Techniques are then used to remove excess coating.

The result is an extremely thin, uniform coating of the product. It is more abrasion resistant than other top coatings, such as paint or varnish. Metals can be used as film for appearance, durability and for electric conductivity.

At present, numerous products are now coated through vacuum coating:

- Optical equipment;

- Tools;

- Computer circuit boards and other parts;

- Window tinting;

- Medical instruments and equipment;

- Aerospace equipment.

Because of the growth of the technology, trade journals have emerged in the industry. A quality trade journal has a number of advantages to manufacturers:

- It provides a means of networking among manufacturers;

- Subscribers can share technical data or seek advice from others in the industry;

- It will provide news in the industry, including the newest products, equipment and techniques;

- It can provide information on upcoming rules and regulations affecting subscribers;

- Members can advertise their unique services or products. This would include suppliers to the industry;

- It provides a means for members to share their latest developments or products;

- Members can obtain new ideas for development, research and development and product application.

The better trade journals in this field will continue to offer print or electronic journals to subscribers. It will also rely heavily on input from its subscribers for new information, technology breakthroughs and other content.

With electronic versions, the subscriber may have the option to tailor information received to its company’s particular interests. In this manner, receipt of superfluous information need not be included in the online/electronic version.